Personal Protective Equipment

Quality and SafetyThe safety and effectiveness of personal protective equipment (PPE) products is critical to protecting user health. At USB Certification, we offer comprehensive testing and certification services to ensure that your PPE products comply with international standards. For manufacturers, retailers and importers, these services allow you to gain a competitive advantage by documenting the quality and safety of your products.

USB Certification performs critical tests such as tensile strength, puncture strength, tear strength, abrasion resistance and cut resistance for your PPE products. These tests prove that your products are safe for users and ensure compliance with regulatory requirements. We also ensure that products are free from harmful substances and do not harm the environment with tests such as organic tin determination, phthalate determination, formaldehyde determination, chromium VI determination and azo dyestuff determination.

USB Certification performs critical tests such as tensile strength, puncture strength, tear strength, abrasion resistance and cut resistance for your PPE products. These tests prove that your products are safe for users and ensure compliance with regulatory requirements. We also ensure that products are free from harmful substances and do not harm the environment with tests such as organic tin determination, phthalate determination, formaldehyde determination, chromium VI determination and azo dyestuff determination.

Textile Products

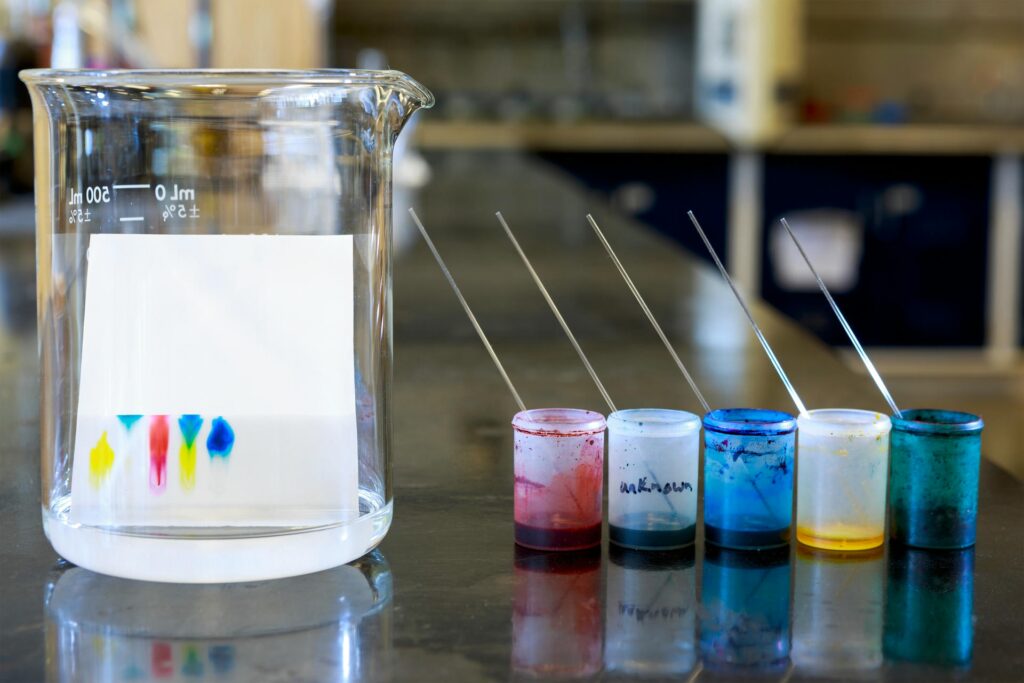

Quality and Safety TestsThe quality and safety of textile products is critical to user satisfaction and brand reputation. At USB Certification, we offer comprehensive testing and certification services to ensure that your textile products comply with international standards. These services help you gain a competitive advantage by documenting the quality and safety of your products.

The tests we provide for manufacturers, retailers and importers include tensile strength, tear strength, puncture strength, abrasion resistance, color fastness and chemical resistance. These tests prove that your products are safe and ensure compliance with regulatory requirements. In addition, tests such as azo dyes, formaldehyde and phthalates assure that products are free from harmful substances and do not harm the environment.

The tests we provide for manufacturers, retailers and importers include tensile strength, tear strength, puncture strength, abrasion resistance, color fastness and chemical resistance. These tests prove that your products are safe and ensure compliance with regulatory requirements. In addition, tests such as azo dyes, formaldehyde and phthalates assure that products are free from harmful substances and do not harm the environment.

Automotive and Technical Textiles

Safety and Quality in Automotive ProductsIn the automotive industry, safety and durability are of paramount importance for user safety and product performance. At USB Certification, we offer comprehensive testing and certification services to ensure that your automotive products comply with international standards. These services help you gain a competitive advantage by documenting the quality and safety of your products.

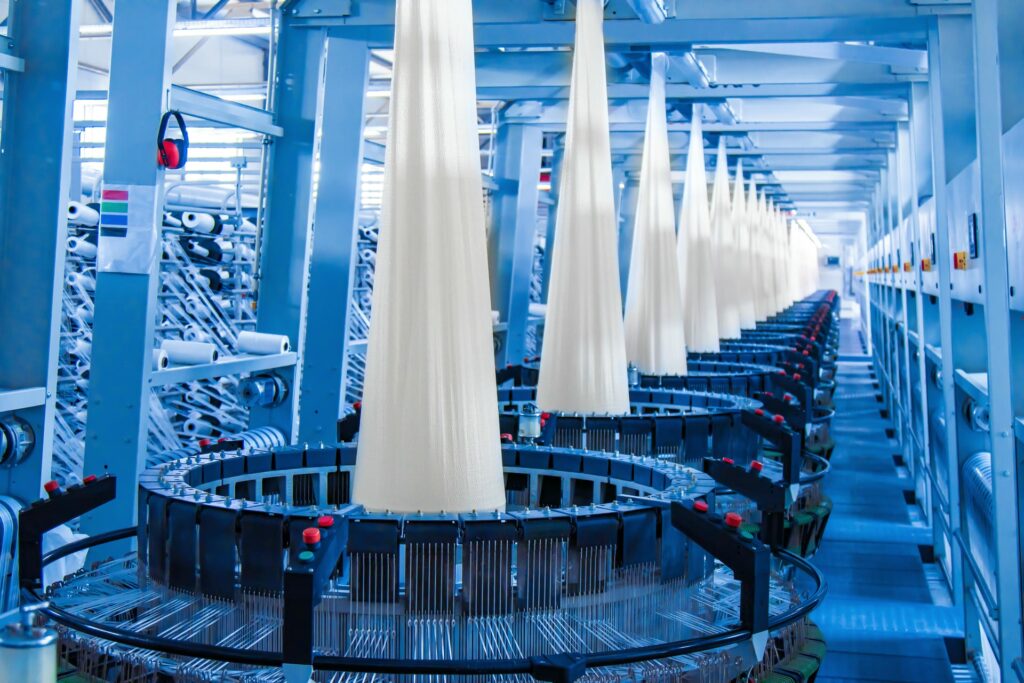

Quality and Safety in Technical Textiles

The quality and safety of technical textiles are critical for industrial applications and user satisfaction. At USB Certification, we offer comprehensive testing and certification services to ensure that your technical textile products comply with international standards. These services help you gain a competitive advantage by documenting the quality and safety of your products.

Industrial Products and Services

Quality and Safety in Industrial ProductsThe quality and safety of industrial products is critical to production efficiency and occupational safety. USB Certification offers comprehensive testing and certification services to ensure that your industrial products comply with international standards. These services cover machinery, equipment and safety equipment used in factories, manufacturing plants and other industrial environments.

Manufacturers must ensure that their products meet all safety and quality standards before they are placed on the market. USB Certification performs durability, performance and safety tests on your industrial equipment. These tests prove that your products are safe and that you comply with regulatory requirements. Retailers and importers must also certify that their products meet high standards. USB Certification analyzes your products and provides the necessary certifications.

Manufacturers must ensure that their products meet all safety and quality standards before they are placed on the market. USB Certification performs durability, performance and safety tests on your industrial equipment. These tests prove that your products are safe and that you comply with regulatory requirements. Retailers and importers must also certify that their products meet high standards. USB Certification analyzes your products and provides the necessary certifications.

Brand and Supply Chain

Brand Reliability and Quality TestingBrand credibility and product quality are critical to customer satisfaction and long-term success. At USB Certification, we offer comprehensive testing and certification services to ensure that your brand and supply chain processes comply with international standards. These services help you protect your brand reputation and gain a competitive advantage by documenting the quality of your products.

The Importance of Testing for Manufacturers, Retailers and Importers

Manufacturers must ensure that their products meet all quality standards before they are released to the market. USB Certification performs quality, durability and safety tests for your branded products. These tests prove that your products are safe and of high quality for consumers and ensure compliance with regulatory requirements. USB Certification offers comprehensive auditing and certification services to ensure your supply chain processes are of the highest standards.

Medical Products

Quality and Safety in Medical ProductsThe quality and safety of medical products are critical to patient health and treatment success. At USB Certification, we offer comprehensive testing and certification services to ensure that medical devices, surgical instruments, implants and laboratory equipment comply with international standards. For manufacturers, retailers and importers, these services help you gain a competitive advantage by documenting the quality and safety of your products.

Proper testing of medical products is of great importance for both patient health and the environment. USB Certification guarantees that your products are free from harmful substances by testing for formaldehyde, azo dyes and phthalates. Retailers and importers rely on these tests to certify that products meet high standards. USB Certification analyzes your products and provides the necessary certificates, thus supporting you to offer reliable and high-quality products.

Proper testing of medical products is of great importance for both patient health and the environment. USB Certification guarantees that your products are free from harmful substances by testing for formaldehyde, azo dyes and phthalates. Retailers and importers rely on these tests to certify that products meet high standards. USB Certification analyzes your products and provides the necessary certificates, thus supporting you to offer reliable and high-quality products.

Packaging & Packaging Products

The Importance of Quality and Safety TestingThe quality and safety of packaging and packaging products is critical for product protection and consumer satisfaction. At USB Certification, we offer comprehensive testing and certification services to ensure that your packaging and packaging products comply with international standards.

Packaging manufacturers must ensure that their products meet quality and safety standards before they are placed on the market. USB Certification performs critical tests such as leak tightness, tensile strength, tear strength, abrasion resistance, puncture resistance and chemical resistance.

Packaging manufacturers must ensure that their products meet quality and safety standards before they are placed on the market. USB Certification performs critical tests such as leak tightness, tensile strength, tear strength, abrasion resistance, puncture resistance and chemical resistance.

Importance of Tests for Environmental and Human Health

Proper testing of packaging and packaging products is essential for consumer health and the environment. By testing for phthalates, formaldehyde, azo dyes and organic tin, we guarantee that they are free of harmful substances.

Shoe, Foot and Leg Protectors

Quality and Safety in ProductsThe quality and safety of footwear, foot and leg protectors are critical to both user health and occupational safety. At USB Certification, we offer comprehensive testing and certification services to ensure that your footwear, foot and leg protectors meet international standards. We test the quality of a wide range of products such as casual shoes, work shoes, safety shoes and sports shoes. For manufacturers, retailers and importers, these services help you gain a competitive advantage by certifying the safety and quality of your products.

USB Certification tests footwear, foot and leg protectors for different uses. Casual shoes are tested for comfort, durability and material quality, while sports shoes are tested for performance, flexibility and durability. Safety footwear is subjected to safety tests such as puncture resistance, abrasion resistance and water vapor permeability. Work shoes are tested for resistance to harsh working conditions, impact protection and ergonomics.

USB Certification tests footwear, foot and leg protectors for different uses. Casual shoes are tested for comfort, durability and material quality, while sports shoes are tested for performance, flexibility and durability. Safety footwear is subjected to safety tests such as puncture resistance, abrasion resistance and water vapor permeability. Work shoes are tested for resistance to harsh working conditions, impact protection and ergonomics.

Gloves, Hand and Arm Protectors

Quality and Safety TestsThe quality and safety of gloves, hand and arm protectors are of paramount importance for both occupational safety and user health. As USB Certification, we offer comprehensive testing and certification services to ensure that your gloves, hand and arm protectors comply with international standards.

We test the quality of a wide range of products such as chemical protective gloves, heat resistant gloves, gloves resistant to mechanical risks. Our tests such as formaldehyde determination, azo dyestuff determination, phthalate determination, dimethylformamide (DMFa) determination and pH determination guarantee that the products do not contain harmful substances and do not harm the user and the environment.

We test the quality of a wide range of products such as chemical protective gloves, heat resistant gloves, gloves resistant to mechanical risks. Our tests such as formaldehyde determination, azo dyestuff determination, phthalate determination, dimethylformamide (DMFa) determination and pH determination guarantee that the products do not contain harmful substances and do not harm the user and the environment.

Polymer, Plastic and Composite Products

Quality and Safety Testing of ProductsThe quality and safety of polymer, plastic and composite products are of paramount importance for both industrial applications and consumer safety. At USB Certification, we offer comprehensive testing and certification services to ensure that your polymer, plastic and composite products comply with international standards. Our services for manufacturers, retailers and importers help you gain a competitive advantage by documenting the safety and quality of your products.

Manufacturers of polymer and plastic products must ensure that their products meet all quality and safety standards before they are placed on the market. USB Certification performs critical tests for your polymer and plastic products, such as durability, chemical resistance and mechanical performance. Polymers and plastics include materials such as polypropylene (PP), polyethylene (PE), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene (PS), polyurethane (PU) and polyvinyl chloride (PVC). We perform the necessary tests to ensure the usability of these materials in different industrial and consumer applications.

Manufacturers of polymer and plastic products must ensure that their products meet all quality and safety standards before they are placed on the market. USB Certification performs critical tests for your polymer and plastic products, such as durability, chemical resistance and mechanical performance. Polymers and plastics include materials such as polypropylene (PP), polyethylene (PE), high-density polyethylene (HDPE), low-density polyethylene (LDPE), polystyrene (PS), polyurethane (PU) and polyvinyl chloride (PVC). We perform the necessary tests to ensure the usability of these materials in different industrial and consumer applications.

Stay One Step Ahead of Your Competitors!Why USB Lab?

Our laboratory ensures that your products stand out in the market by offering tests that comply with the most up-to-date requirements and standards in the industry. With detailed test reports and analysis that your competitors do not offer, you can provide your customers with concrete evidence of your product quality.