RoHS Testing and Implementation Process

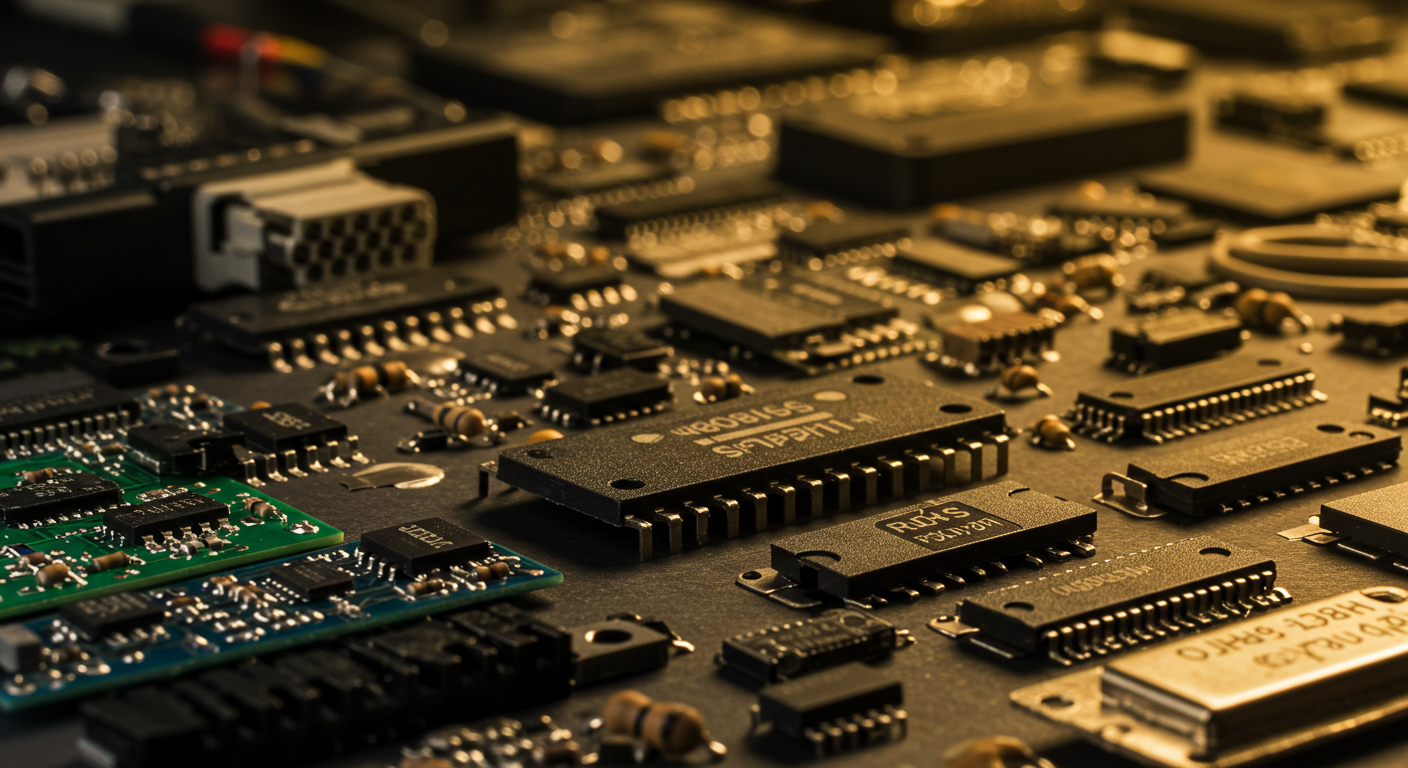

RoHS testing is a testing process to limit the use of environmentally hazardous substances in electronic products. These tests, conducted in accordance with international standards such as IEC 62321 series, ASTM F2617-15 and EN IEC 63000, determine the presence of harmful elements such as lead (Pb), cadmium (Cd), mercury (Hg), chromium (Cr) and bromine (Br) in products. This ensures that electronic devices are produced in a way that is both environmentally friendly and suitable for human health. RoHS testing plays a critical role in meeting legal requirements as well as ensuring a sustainable production process.

How is RoHS Testing Performed?

RoHS testing is performed using spectrophotometer instruments. The testing process begins by analyzing samples of electronic components. The samples are exposed to X-ray radiation and examined in detail for harmful substances. This method allows for fast and precise results.

The amount of harmful elements present in the tested products is assessed for compliance with RoHS regulations. The analysis kits used include different types of tests:

- RoHS Basic Screening Analysis (5 Element Analysis): Cadmium (Cd), Lead (Pb), Mercury (Hg), Chromium (Cr) and Bromine (Br) are measured.

- RoHS + Halogen Screening Analysis (6 Element Analysis): In addition to the basic 5 elements, Chlorine (Cl) is analyzed.

- RoHS + Halogen + Antimony Screening Analysis (7 Element Analysis): In addition to 6 elements, Antimony (Sb) is measured.

In these tests, special measurement techniques are applied, taking into account the homogeneity, surface properties and composition of the sample.

Importance and Benefits of RoHS Testing

RoHS testing not only ensures that legal requirements are met, but also minimizes the negative impact of electronic products on the environment and human health. These tests, which encourage environmentally responsible production, make it possible to offer safer products to consumers.

The benefits of RoHS testing include:

- Environmentally friendly production: Contributes to the conservation of natural resources by limiting harmful substances.

- Legal compliance: Compliance with international regulations such as the European Union’s RoHS Directive (2011/65/EU), EN IEC 63000:2018.

- Market competitiveness advantage: RoHS compliant products increase competitiveness in the global market and facilitate export processes.

- Brand reputation: Environmentally responsible production processes enhance brand reputation and customer trust.

In addition, RoHS testing can be considered in conjunction with other environmental regulations such as WEEE (Waste Electrical and Electronic Equipment Directive) and REACH (Registration, Evaluation, Authorization and Restriction of Chemicals Regulation ) to help ensure compliance with sustainable production standards.

Every stage is under control…

Contact Us Now for Testing Service!

Contact us for more information on RoHS testing or to arrange testing.

Application Areas of RoHS Testing

RoHS testing can be applied in almost every area of the electronics industry. Below are some examples of the uses of RoHS testing:

- Consumer electronics products (telephones, computers, televisions, etc.)

- Industrial equipment and circuit boards

- Plastic and polymeric components

- Monitoring heavy metal and halogen content in manufacturing processes

- Hazardous element analysis in composite materials

Through RoHS testing, manufacturers can guarantee that their products comply with RoHS regulations. Ensuring compliance with RoHS standards in production processes increases competitiveness in the global market and contributes to the fulfillment of environmental and legal responsibilities.

Why Work with Us?

Detect harmful elements in your products with RoHS testing in accordance with IEC 62321-3-1. We offer reliable solutions for environmentally friendly and internationally standardized production.