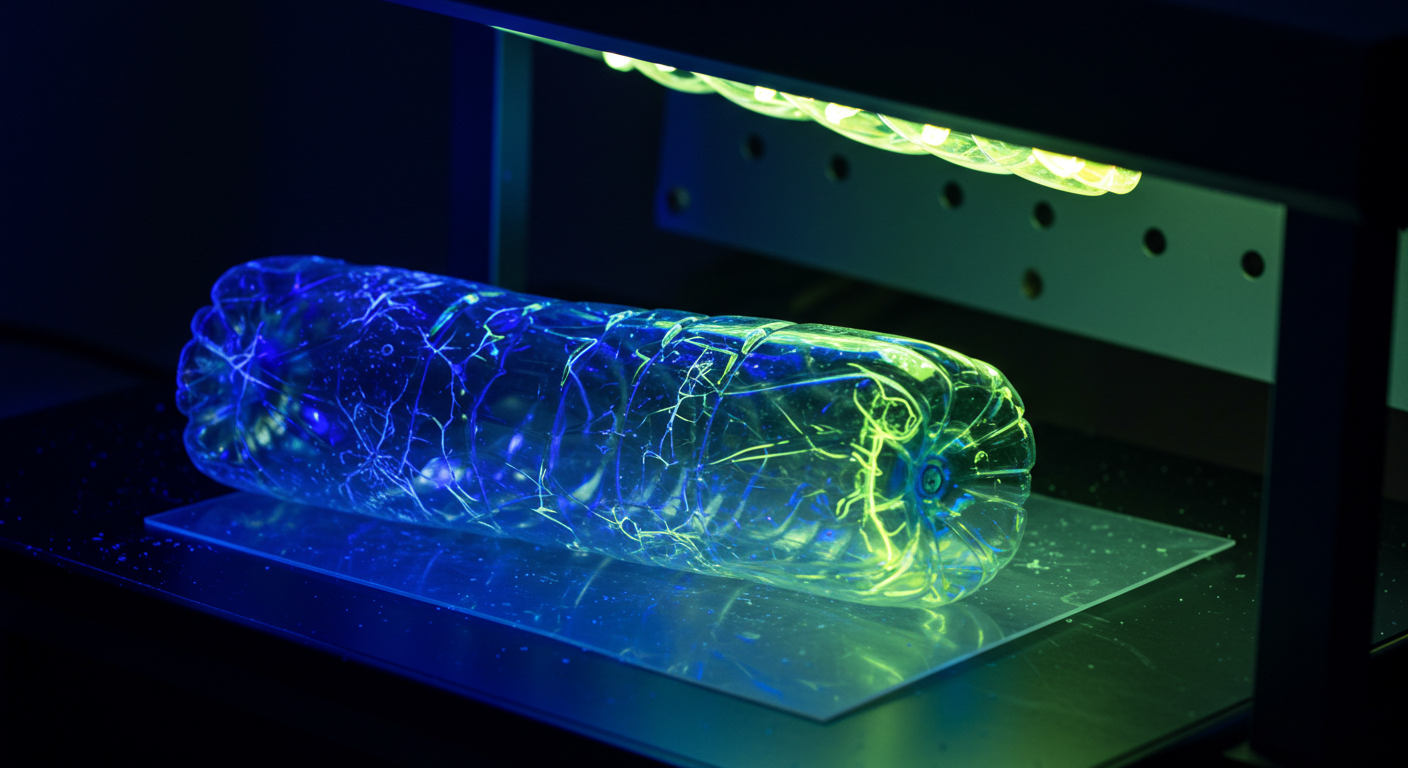

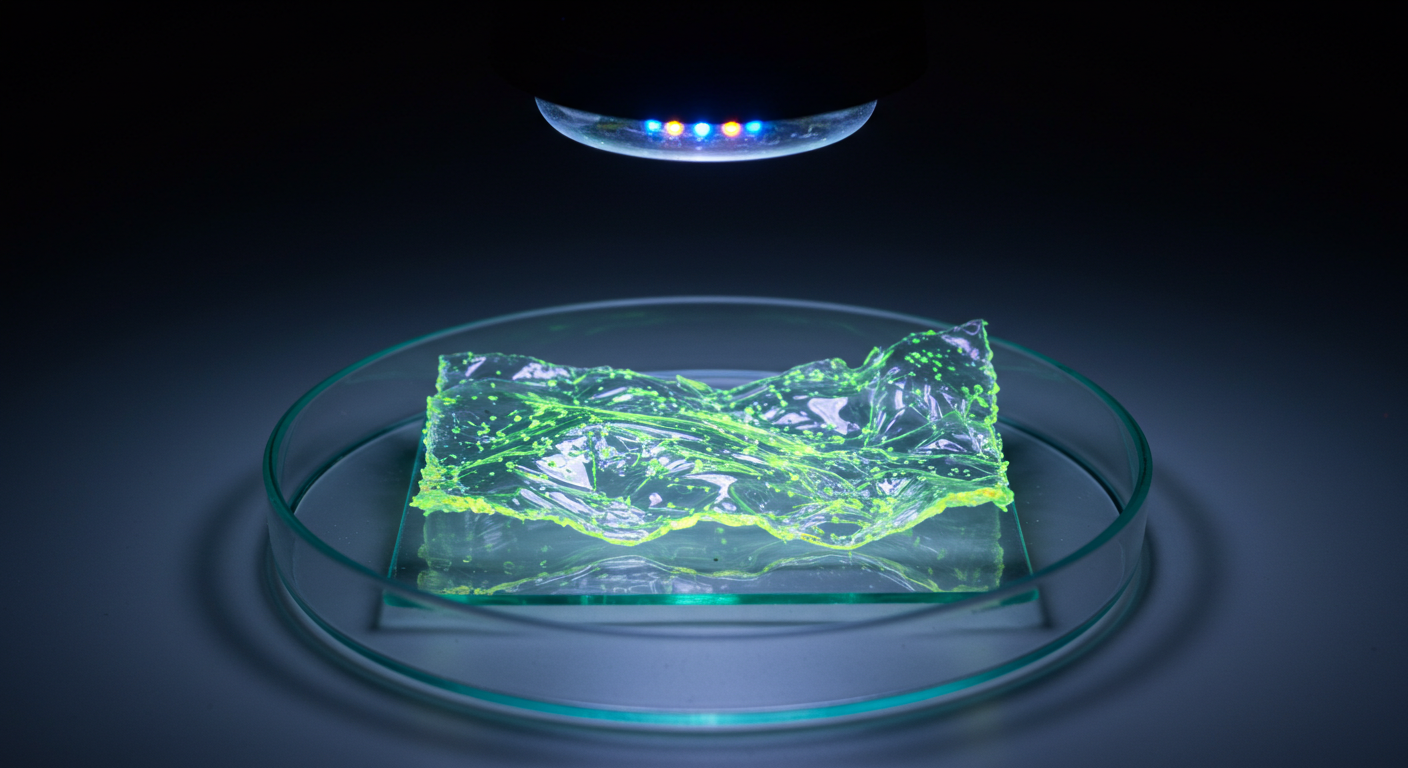

UV Aging Test is a test to simulate the effect of sunlight on plastic materials in the long term. This test, which is carried out in accordance with ISO 4892-3 and ASTM G 154 standards, provides information about the durability and lifetime of plastics against outdoor conditions by exposing them to UV rays and humidity cycles in a laboratory environment.

How is UV Aging Test Performed?

Samples are tested under specific UV light sources and humidity cycles to observe possible effects such as material discoloration, cracking and physical degradation. This test simulates how plastics will behave in the external environment and evaluates their long-term performance. As a result of the test, potential damage to the material is identified and estimates are made about its lifetime.

Importance of UV Weathering Test

Plastic materials may show discoloration, cracking and deterioration in physical properties over time due to prolonged exposure to sunlight and weather conditions outdoors. The UV Weathering Test ensures that these negative effects are detected at an early stage, ensuring that the material is long-lasting and durable.

Uses of UV Weathering Test

UV Weathering Test is widely used to determine the durability of plastic materials, especially those suitable for outdoor use. This test is important for testing the durability of plastic products such as furniture, wood-based boards, building materials against outdoor conditions.

Every stage is under control…

Contact Us for Information and Support

Contact us for more information on UV Weathering Testing and for testing in accordance with ISO 4892-3 or ASTM G 154 standards!

Benefits of Testing

Outdoor Durability: Used to determine how resistant plastics are to outdoor conditions.

Evaluation of Product Performance: The performance of materials against external factors such as sunlight and moisture is measured.

Quality Assurance: It predetermines possible deterioration of plastics such as discoloration and cracking in long-term use, thus ensuring product quality.

Application Areas of the Test

Furniture Production: Used to test the durability of outdoor furniture.

Building Materials: Evaluates the suitability of PVC and other plastic building materials for long-term use outdoors.

Automotive Sector: Tests the resistance to UV radiation of non-vehicle plastic parts.

Conclusion: Improve the Durability of Plastic Products with UV Aging Testing

The UV Weathering Test in accordance with ISO 4892-3 and ASTM G 154 standards plays an important role in determining the resistance of plastics to outdoor conditions. This test is used to ensure the longevity of products and to identify poor quality materials in advance.

Why Work with Us?

Contact us today for more information on UV weathering testing or to benefit from our testing in accordance with ISO 4892-3 and ASTM G 154 standards. Our team of experts is here to guarantee the outdoor durability of your plastic products!